Manager Zhou

Leave a message

summary

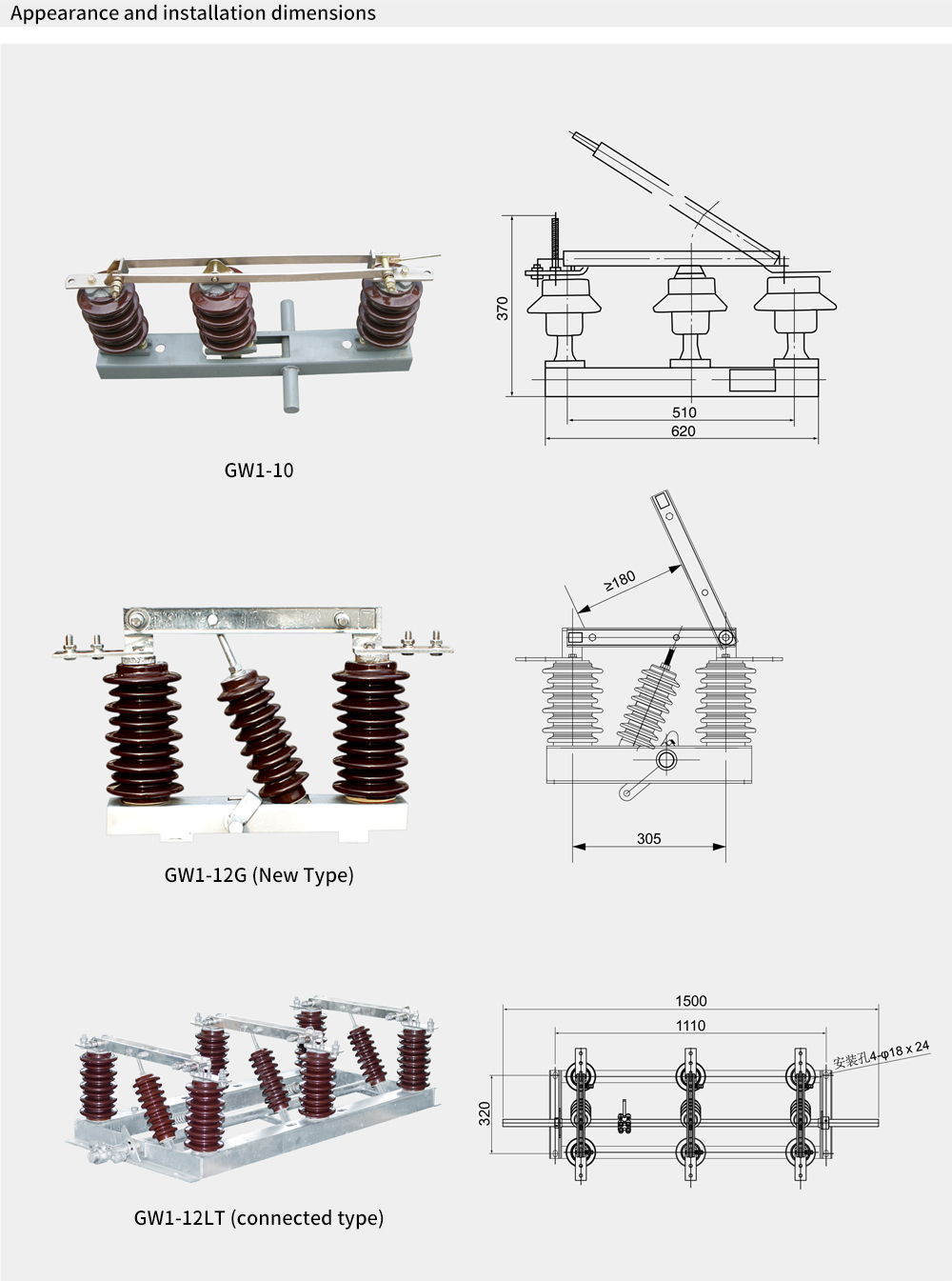

GW1-10 outdoor High-voltage isolation switch is suitable for installation on outdoor high-voltage distribution equipment lines, used to cut off and convert lines when there is voltage and no load. This product is a three-phase electrical appliance composed of three separate single isolation switches. Each single isolation switch has the same components, such as base post insulators, front and rear static contacts, switch blades, and arc angles.

The GW1-12G outdoor high-voltage isolation switch is a type of switch that addresses a series of issues with the original GW1 switch and is modified according to current national standards and equipment modifications. The switch itself is equipped with a Grounding switch, which can effectively prevent misoperation such as "live grounding wire hanging and grounding wire closing", and the operator does not need to hang another grounding wire. This product has excellent electrical and mechanical performance, and has met the requirements of the national standard GB1985 and its revised version, as well as the electrical standards IEC129 and IEC694. It is a product of the current 10kV outdoor isolation switch.

The GW1-12LT outdoor high-voltage isolation switch is a double column vertical opening type, equipped with a manual operating mechanism of CS8-5D rainproof type and an electric operating mechanism of CX-6 type. This product is a three-phase common chassis knife switch, which can be divided into a chassis, insulators, and conductive parts. The chassis is composed of a frame welded with a rotating shaft, a bent plate, and angle steel. Six ceramic insulators are fixed on the chassis, with each two forming one. The rotating shaft is equipped with a three-phase operating insulator, which is used to operate the opening and closing movement of the three-phase knife switch. The conductive part is composed of contacts, knife switches, and contact seats, which are compressed by springs. When the switch is opened, the operating lever drives the rotating shaft to rotate, causing the operating insulator to push the switch upwards and separate the switch and the contact. The switch rotates around the contact seat, and the contact also moves upwards to the opening position under the driving of the switch. When closing, the operating lever drives the rotating shaft to rotate, causing the operating insulator to pull the switch blade and rotate downwards. After encountering the contact, it drives the contact to rotate and turn to the closing position together.

Technical parameters of GW1-10, 15, 20 (DW) outdoor high-voltage isolation switch

| NO. | Item | Unit | Data | |||||||

| 01 | rated voltage | kV | 10 | 15 | 20 | |||||

| 02 | maximum working voltage | kV | 12 | 7.5 | 23 | |||||

| 03 | Rated Absolute Edge level | 1-minute power frequency withstand voltage (effective) Value) | to ground | kV | 40 | 40 | 50 | |||

| fracture | kV | 47 | 47 | 60 | ||||||

| Lightning impulse withstand voltage (peak value) | to ground | kV | 105 | 105 | 125 | |||||

| fracture | kV | 120 | 120 | 145 | ||||||

| 04 | Rated frequency | Hz | 50 | |||||||

| 05 | Rated current | A | 200 | 400 | 630 | 1250 | ||||

| 06 | 4-second thermal stability Current (effective) Value) | kA | 6.3 | 12.5 | 20 | 31.5 | ||||

| 07 | Dynamic stable current (Peak value) | kA | 16 | 31.5 | 50 | 80 | ||||

| 08 | Supporting organization | CS8-1, CS8-D, CS8-5 rainproof manual mechanism Or CX6 electric operating mechanism | ||||||||

When installing and using the GW1-10 isolation switch, the following environmental conditions should be noted:

Altitude: usually not exceeding 1000m (some data indicate that it can reach 2000m or 3000m, requiring special design or verification).

Environmental temperature: generally ranging from -40 ° C to+40 ° C.

Wind pressure: not exceeding 700Pa (approximately equivalent to a wind speed of 34m/s).

Seismic intensity: not exceeding 8 degrees.

Ice thickness: not greater than 10mm.

Pollution level: Ordinary type is suitable for areas with level 0 pollution; Anti pollution type (W) can be used in heavily polluted areas.

Installation location: There should be no substances that seriously affect insulation and conductivity, and no frequent and severe vibrations.

When choosing the GW1-10 isolation switch, the following points can be considered:

Rated parameters: Ensure that its rated voltage, rated current, dynamic stability current, and thermal stability current meet the requirements of the line.

Environmental adaptability: Select ordinary or anti pollution type (W) according to the environmental conditions of the installation area (such as pollution level, climate).

Grounding requirement: If convenient hanging of grounding wire and prevention of misoperation are needed, an improved model with grounding knife switch (G (D)) can be selected.

Operation mode: Usually equipped with manual operating mechanism (such as CS8-1, CS8-5), but there is also an optional electric operating mechanism (CX-6).

Click here to watch the assembly process of the indoor Rotary isolation switch

Picture

CERTIFICATE ISO9001

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Oil&Gas exploited

Automotive Manufacturing

Transportation & Dlistrlbutlon

Manufacture

Industrial Construction

Green Energy

Copyright ? 2024 All Rights Reserved

Back to top

Comment

(0)